Beauty and cosmetics are going through a major shift when it comes to packaging. Younger consumers, especially Gen Zers, want more sustainable packaging options. While there has been a great deal of innovation when it comes to food retail and food delivery packaging, truly sustainable beauty packaging options are still limited given the many constraints. Packaging that is liquid friendly, anti-leak, anti-microbial and that enables products their skincare performance attributes while also being fairly long-lasting- not quite the same thing as a salad box that a consumer uses for 20 minutes. So what’s a woke beauty brand to do? Enter On Repeat, a just-launched solution that enables cosmetic and personal care companies to offer a product refill service without any stress- the On Repeat service takes care of everything from fulfilling the refill orders to shipping them out to your customers in your branding. This is truly the future of circular packaging and we wanted to know more so we spoke to co-founder Benjamin Proctor to get all our questions answered.

Tell us about On Repeat: what is it and what does it do? What’s the tech behind it?

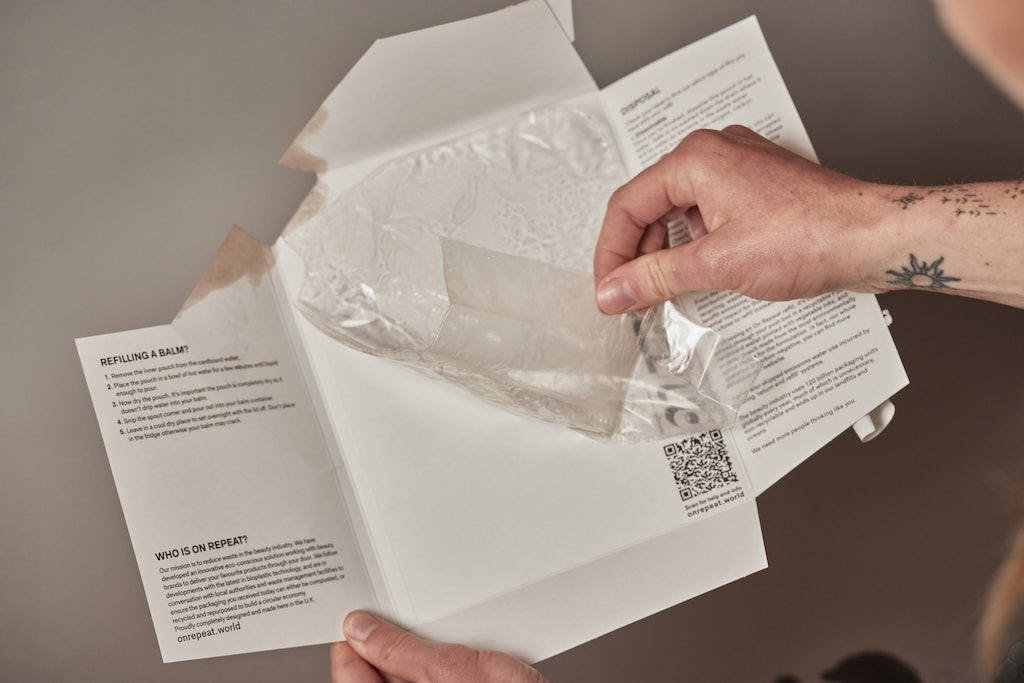

We’re a B2B packaging and fulfilment service helping skincare brands in the UK offer refills to the their customers. We offer an all in one solution for brands who want to reduce waste in the beauty industry. We integrate with a brand’s e-commerce store where their customers can choose a refill option; these orders come through to us and then we fill the product to order and send it to the customer in our biodegradable packaging. The packaging is also in large letter size so it fits through the letterbox so there’s no need to stay in all day waiting for the delivery. The customer then decants the product into their existing bottle and disposes of the packaging.

How did you come up with the idea?

Our co-founder, Micaela, owns a skincare brand and wanted to find a way to offer refills to her own customers. The concept and packaging design comes from her creative mind. Once we got talking we realised the complexities of the materials how they can be used with liquids, but also how biomaterials are marketed and how easily consumers can dispose of them. We’ve spent the last two years testing materials, but also going deep into researching the waste stream and collection infrastructure in the UK to make sure this works.

What is your background? What made you become the (co) founder of a refill service?

My background is actually in food and drink. I had a business in London importing and distributing wine and cheese from Europe. I was looking for my next project and once we got talking about On Repeat, I realised it was a brilliant idea and have since become obsessed with plastic alternatives and how we can make this work.

There are other refill services out there, how is yours different?

For consumers, our service is straightforward and easy for them to buy their favourite products. You don’t need to send the bottle back to be washed out – you keep your existing bottle and refill it. The packaging is dissolvable or compostable, and it really works. For brands, you’re offering your customers a zero-waste alternative when buying your products. Our warehouse software integrates easily with your e-commerce store and we take care of the warehousing, stock management and fulfilment of the refill orders.

Can you share more about the packaging you developed for your service?

It comes in two parts – the pouch is made from different materials according to the product and where it’s disposed of. Currently, we have a dissolvable option and a compostable option. The pouch is wrapped in a FSC certified cardboard wallet printed with vegetable inks which is fully recyclable. The postal packaging is made from recycled cardboard and the packing slips are printed on recycled paper. We’ve also just bought a refillable printer which I’m so excited about!

How will you address the issue that every brand has different requirements?

This has always been on our minds. It’s about adapting to clients’ needs and seeing how we can find a solution. We’re able to offer refills on most products, including balms. It’s not just brands that have different requirements, but the rubbish collection where you live too. We are constantly researching the best materials to use and how these will work in different environments. Part of our job is to make sure the two match.

You are currently addressing the UK market. Is the service geographically scalable? Can you go global?

Absolutely. We’ve already had some interest from brands in Europe and the US. There’s no one size fits all solution to reducing waste in packaging, so it’s important we look at each region and adapt accordingly.

What’s the end goal here? Where are you looking to be in 10 years?

Our aim is to reduce waste in the beauty industry. Refills are the way forward and we’d like to be part of that change. And in 10 years? There’s no reason we can’t move into packaging products other than skincare too. I still love wine so…

Why don’t we refill enough? What are the major barriers standing in the way in your view?

Some of it is to do with changing our habits – rather than buying a new bottle of product, why not choose a refill? I remember supermarkets phasing out plastics bags. You forget to bring your own the first few times, but then you make sure to leave a few by the front door so you remember next time and now it’s quite normal.

For us it’s about making the change easy for people to incorporate into their lives – designing out waste and simplifying the packaging. It’s also about local government making it easier for people to dispose of these items. Collections vary so much depending on where you live and this needs to be simplified.

How can packaging companies and buyers work with you?

It’s all a group effort – whether you’re a consumer, a brand or make the raw materials. We’re always looking for new partners: From people innovating in the biomaterials sector or companies to manufacture pouches and wallets.

Lead image courtesy of On Repeat.