Mycelium is an exciting new material gaining a lot of supporters in the circular economy. But what is mycelium? What are its applications? And what makes it so sustainable? Is it the greenest styrofoam alternative out there? Below, is an introductory guide to mushroom packaging.

What is Mycelium?

Mycelium is the root network of a fungus, usually found below the ground (mushrooms are the other part which we see above ground). It consists of a network of branching, interconnected fine threads which can grow into any shape, from delicate structures to tightly packed masses. And mycelium has no size limit, with the Armillaria network covering nearly 2,400 acres.

How is Mycelium used in packaging?

Mycelium is a completely natural material that is lightweight, strong and cheap to produce making it an increasingly attractive and cost-competitive alternative option to fossil fuel-derived materials. One major benefit for manufacturers is the ease with which it can be molded into different shapes, with the material literally growing to fill the moulds.

The current market leader in mycelium pack-tech is Ecovative Design, based in New York, USA. Their two packaging solutions are a rigid composite material, MycoComposite, and a 100% mycelium flexible foam, MycoFlex.

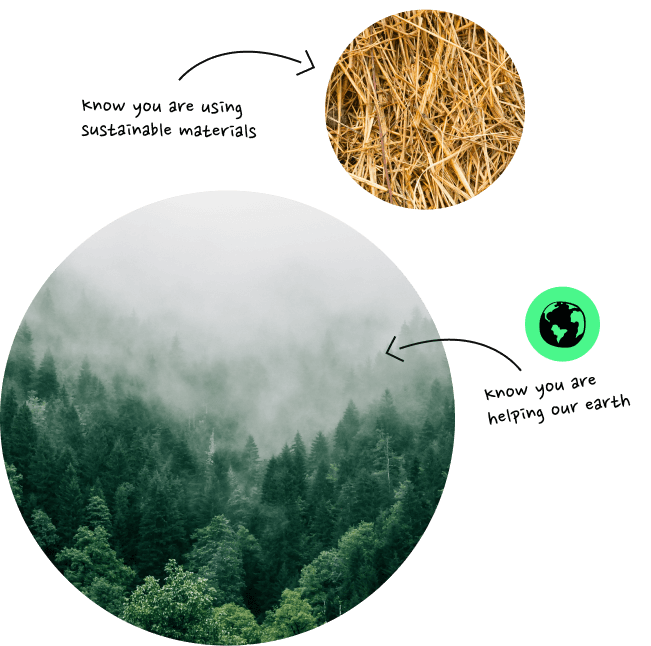

MycoComposite uses mycelium as a binder together with agricultural byproducts such as woodchips or straw to create rigid shapes that can be used for protective packaging. It is designed to replace expanded polystyrene (EPS), also known as styrofoam, which holds a dominant position in packaging due to its low cost, thermal insulation and structure.

MycoFlex is a pure 100% mycelium product made into high-performance flexible foams as a sustainable alternative to polyurethane and other expanded plastic foams. These foams can be used across a number of applications, such as cosmetics, luggage and footwear.

What products are packaged in Mycelium?

Mushroom packaging is taking off with Ecovative, which raised $60 million this year, licensing its technology for worldwide manufacture. There are currently 4 producers worldwide: in the US, UK, the Netherlands and New Zealand.

The MycoComposite has gained the most commercial success, with furniture giant Ikea, and computer company Dell, entering into a partnership to use the material in its furniture packaging to replace polystyrene. It is also popular with eco-conscious, luxury consumer brands – especially those with products that require additional protection during shipping.

What are the other uses for Mycelium?

Mycelium is incredibly versatile. The fungus is being used in other verticals such as skincare sponges, cruelty-free leather, and even alt-protein substitutes. In fact, Ecovative spun out a separate fungi meat company to meet market demand in this category. The young startup, Atlast Foods Co, well known for its bacon alternative, has already raised $40 million. On the fashion front, Mycoworks bagged $45 million to scale up its animal-free leather material and recently announced a partnership with Hermes.

What makes Mycelium so sustainable?

Mycelium has gained a lot of sustainability advocates for a number of reasons:

- It is a completely natural product. Mycelium is a completely natural material found in the environment and the species used have no toxic effects.

- Made from a renewable resource – no fossil fuels and infinitely renewable.

- Easy to grow, needing very little water, light or space to produce at an industrial scale.

- Excellent end-of-life performance – mycelium is home compostable which is highly desirable for single-use applications such as packaging. It can even degrade in the natural environment, returning nutrients to the soil. Some companies even infuse wildflower and grass seeds into their mycelium packaging to make them bio-contributing.

There are some detractors for mycelium, mainly highlighting its carbon footprint in production. As a fungus, it actually takes in oxygen and releases CO2 as it grows – the opposite of plants. There are concerns that large-scale cultivation of mycelium could lead to increased CO2 levels in the atmosphere.

Conclusion

Mycelium certainly seems like a wonder material and it’s proving successful commercially too. Furniture giant IKEA, is phasing out all its EPS packaging to replace it with mushroom packaging in the form of mycelium foams and composite boards. Polystyrene has a long-held dominant position in packaging due to its performance with respect to heat insulation, toughness, and low weight. But these innovations are threatening a new normal.

Lead image created by SourceGreenPackaging.com.