New and improved bioplastics are hitting the manufacturing world, seemingly, every week, but what about those that truly started the trend? Made from renewable sources and fully biodegradable, the original bioplastics offered an optimistic look at how packaging production could evolve but are we being too quick to forget about the likes of PLA, in the face of even more promising alternatives such as PHA?

What is PLA?

PLA is a natural polyester commonly made from cornstarch or sugarcane. When ready to use, it has properties not dissimilar to polypropylene, polyethylene, or polystyrene.

First discovered all the way back in the 1920s, by Wallace Corothers, the inventor of Nylon, PLA was never fully realised as a commercial material but by 2010, it was the second most valuable bioplastic in the packaging market, according to consumption figures.

PLA is also known by the following monikers:

- Polylactic Acid

- Polylactide

How is PLA made?

As with most bioplastics, a controlled environment that encourages fertilisation is needed for PLA synthesis to occur, but as opposed to needing bacteria to grow granules that can be harvested, as with PHA, carbohydrates are the most important element here.

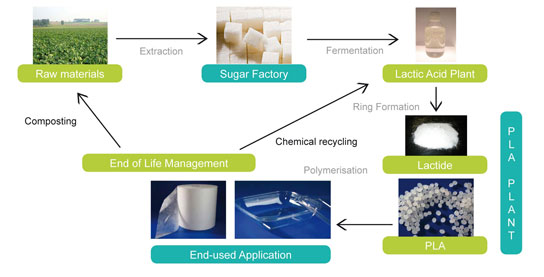

Typically, cornstarch, sugarcane and tapioca starches are used, depending on manufacturer location. Starches are separated from the initial material, before being mixed with acid or enzymes and finally, heat, which allows dextrose to be isolated and this is where the magic happens. Fermentation of the dextrose leads to lactic acid production and that’s the basic building block of commercially viable PLA. From here, polymerisation occurs so that volume can be multiplied and a finished bioplastic produced quickly and cost-effectively.

The following diagram breaks the process down into a simple visual:

Notably, PLA can be made using already in-situ manufacturing equipment originally designed to create petrochemical plastics, meaning that the price to switch over to a more responsible alternative is negligible and not a prohibitive reason to stall.

Who is using and making PLA?

PLA is being used throughout multiple high-value industries, demonstrating a clear demand for bioplastic evolution. Thanks to the ease with which it can be made, using said existing equipment, manufacturers can offer an environmentally beneficial alternative to traditional plastics, which offers clients an opportunity to update their branding with greener marketing.

Current industry users include:

Food packaging: As a food packaging application, PLA is cost-effective and Generally Recognised as Safe (GRAS), though without additives it can be limited in the number of products it can be used to make. There is a risk of lactic acid leaching, when PLA comes into contact with certain liquids, though tests have indicated that levels are not harmful to humans. It has been used to produce cups, tea bags, bottled and films.

Medical: Similarly to PHA, PLA is bio compatible and can be used within the human body in the form of medical aids and support systems. The risk of infection is minimal and the range of applications is vast, from screws to plates and even tissue engineering. PLA dissolves in the body without toxic repercussions and is a lighter alternative to traditional metal.

Construction: A slightly tenuous one here. PLA can be used for very specific applications, such as insulation, but because it degrades fully, use is very limited right now. No structural uses are yet approved.

Textiles: As fabric composition continues to dominate the evolution of the fashion industry, PLA has risen through the ranks to become a viable alternative to synthetic polyesters. It is particularly useful for sportswear that requires high levels of breathability coupled with a lightweight feel, but its most industry-changing property is its recyclable nature. It has been heralded as a key player in the move towards a circular fashion economy.

Some of the largest manufacturers of PLA are:

A joint-venture between Cargill (US) and PTT (Thailand), NatureWorks has some very exciting ideas being tested. Already using plants in an earth-positive way, the company transforms greenhouse gases into sugars that can, eventually, be polymerised. This technology is being improved all the time and there is scope to negate the use of plants as well. Using abundant feedstocks, NatureWorks has, since 1989, looked to keep improving the potential of PLA and today is highly respected for its flagship end product, Ingeo. It has a presence in more than 10 countries, supplying businesses in the US, Europe, Japan and Asia Pacific.

One of the leading manufacturers of now only reusable but also sustainable bags, WeforYou produces biopolymer shoppers in its facilities in China and supplies them throughout the world. The company speaks of a holistic approach from start to finish, which sees raw bio materials being transformed into a lasting and recyclable product.

Another joint venture, this time between Total (France) and Corbion (NL), Total-Corbion demonstrates an important shift in traditional production methodologies for existing petrochemical companies. Luminy® is the key offering here and comes in two formats, standard and high-heat applications. Created for a vast array of uses, it has already been utilised as food serviceware, food packaging and within the 3D-printing sector. The production facility is located in Thailand, with customers supplied globally.

Why is it better than plastic?

There are many ways in which PLA is an environmentally superior alternative to standard plastics but the main benefits are reduced carbon footprints during production, cost-effectiveness of the switch to manufacture and of course, the recyclable nature at EOL. This being said, PLA isn’t without its critics or downsides.

Arguments for and against PLA

There’s no denying that in comparison to regular plastics that have no option but to be sent to landfill at EOL, PLA is an attractive and environmentally aware response to a growing need. It’s important to look at the full picture though, including criticisms, limitations and potential issues that stem from PLA use.

Pros:

- PLA is made from entirely renewable raw materials and is biodegradable, so it will return to natural materials as it decomposes. Optimal conditions will significantly speed up the process, but even when slower, the degrading will be complete. It is also listed as being compostable.

- It can be used in regular petrochemical plastic manufacturing plants, meaning no initial expenditure is needed in terms of infrastructure to work with it.

- PLA is a thermoplastic, so it can be reshaped and moulded a number of times, without affecting its mechanical structure.

- It can be made worldwide, using a variety of carbohydrate sources that are grown locally, allowing for further carbon footprint reductions.

Cons:

- It is still more expensive than petrochemical plastics, making it prohibitive to some.

- Critics have been quick to decry the use of food crops as raw materials, though this was more in 1st gen PLA and non-edible food crops have since been used.

- Though it can be composted, it does not degrade into matter that offers any nutrients or benefits to the earth. The end material is therefore not ‘compost’. It will make soil more acidic too.

- It is recyclable, both chemically and mechanically, but this requires speciliased facilities.

- The low melting point also makes PLA unsuitable for certain applications that will necessarily involve heat.

- It is not a structurally protective plastic alternative and offers oxygen and moisture permeability, meaning that only short-term food storage is advised.

The use of PLA in packaging

Taking hot food and beverages out of the equation, PLA is a great option for packaging materials, with the Food and Drug Administration (FDA) recognising it as suitable and safe. Applications are varied, ranging from plastic water bottles and cups to flexible films, extruded containers and moulded packages, such as yoghurt pots. Packaging should be used as a short-term food storage option, making it ideal for fresh and short shelf-life items.

Additives can be included to open up a wider array of packaging solutions, including those for high-heat applications, though this raises questions as to the environmental credentials of the finished product and can impact EOL responsibilities for manufacturers.

Did PLA start the bioplastics trend?

In short, yes. PLA should not be overlooked in terms of the impact it had on highlighting alternatives to traditional petrochemical plastics and though it has its critics and some would say it has been superseded by the likes of PHA, it is continuing to evolve. If its shortcomings linked to heat and easy recyclability can be improved upon, PLA could once again be hailed as a future solution that everybody needs to get onboard with. So perhaps the question should be: will PLA be the ultimate bioplastic that not only started but also ends the discussion about viable environmental packaging solutions?

Lead image by Kindel Media from Pexels